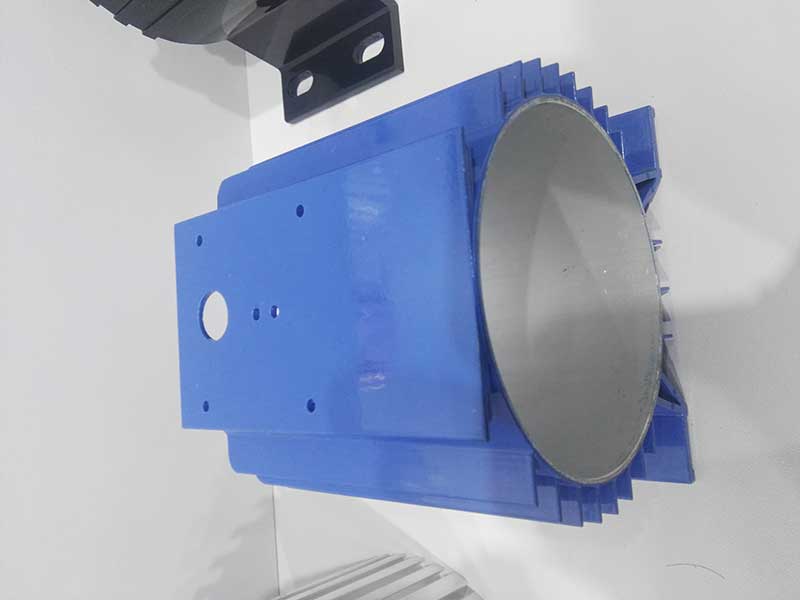

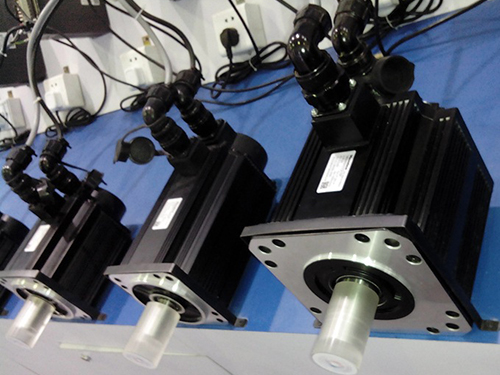

Due to its good ductility and reduced specific gravity, aluminum alloy motor shell has the advantages of light weight, high strength, large cooling area, good heat dissipation, good thermal conductivity, high tensile strength, beautiful surface, etc Widely used in generator, starting motor, micro motor and other components.

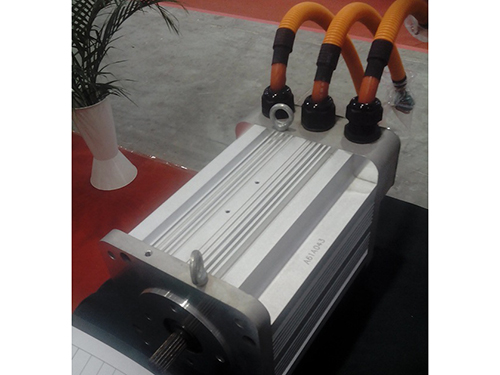

With the in-depth popularization of energy conservation, emission reduction and low-carbon concepts, the new energy automobile industry is also experiencing the upsurge of R & D and mass production Aluminum alloy water-cooled circulating cooling shell is widely used as supporting products of new energy vehicles.

What is the aluminum extruded water-cooled circulating cooling shell?

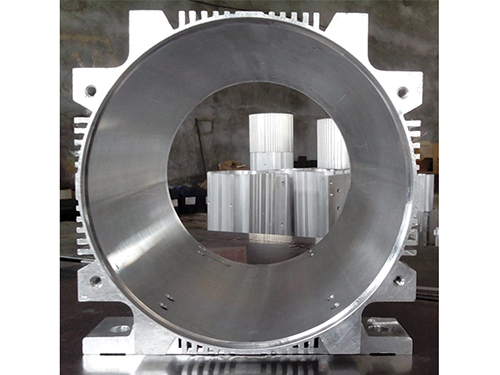

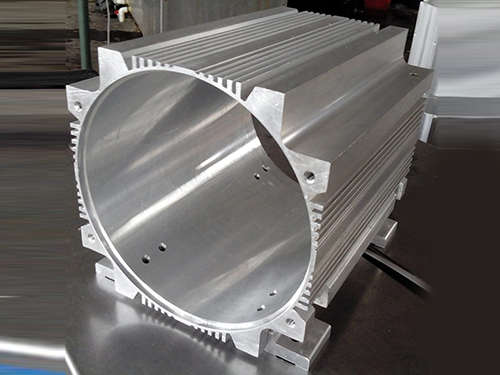

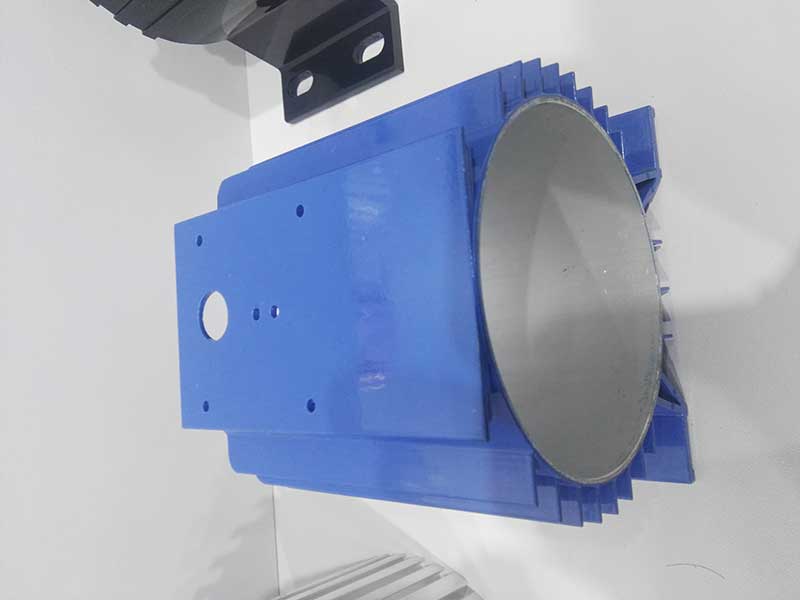

The aluminum water cooled motor shell is extruded And carry out the cooling water circulation in the shell inner liner Take away the heat generated when the motor is running This process makes the motor shell almost without heat dissipation Water circulation replaces cooling fans.

The research and development of aluminum extrusion motor shell has successfully replaced the aluminum die casting motor shell The problem of aluminum die casting motor shell is the poor density of material, which is easy to cause casting defects such as porosity, porosity, etc. the defects of poor surface casting roughness and corrosion resistance are successfully avoided.

Application:

Henan Chalco produced aluminum extrusion motor shell (or extrusion aluminum motor shell) has better performance than other materials: lightweight; low noise; using Aluminum Alloy 6063 as material, through hot extrusion, energy saving and high efficiency Inner hole concentricity ≤ 0.07mm The water-cooled aluminum alloy extrusion motor shell produced by our company breaks through the technical problem of motor heat dissipation. Its water jacket structure, circulating water cooling mode, unique special profile extrusion process, special argon arc welding process and shaping process are adopted, and the first spiral water dividing tank on the inner wall is created, which effectively improves the heat exchange efficiency and heat dissipation performance of motor products

Aluminum extrusion motor shell is mainly used in micro motor, environmental protection air conditioning motor, water cooling air conditioning motor, air compressor motor, negative pressure blower, motor, electric tricycle motor, cooling tower machine, electric tool motor, gear motor, etc.

1. Specs:

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

Mill finish surface:

Color anodized surface:

Color Painted surface:

With the in-depth popularization of energy conservation, emission reduction and low-carbon concepts, the new energy automobile industry is also experiencing the upsurge of R & D and mass production Aluminum alloy water-cooled circulating cooling shell is widely used as supporting products of new energy vehicles.

What is the aluminum extruded water-cooled circulating cooling shell?

The aluminum water cooled motor shell is extruded And carry out the cooling water circulation in the shell inner liner Take away the heat generated when the motor is running This process makes the motor shell almost without heat dissipation Water circulation replaces cooling fans.

The research and development of aluminum extrusion motor shell has successfully replaced the aluminum die casting motor shell The problem of aluminum die casting motor shell is the poor density of material, which is easy to cause casting defects such as porosity, porosity, etc. the defects of poor surface casting roughness and corrosion resistance are successfully avoided.

Application:

Henan Chalco produced aluminum extrusion motor shell (or extrusion aluminum motor shell) has better performance than other materials: lightweight; low noise; using Aluminum Alloy 6063 as material, through hot extrusion, energy saving and high efficiency Inner hole concentricity ≤ 0.07mm The water-cooled aluminum alloy extrusion motor shell produced by our company breaks through the technical problem of motor heat dissipation. Its water jacket structure, circulating water cooling mode, unique special profile extrusion process, special argon arc welding process and shaping process are adopted, and the first spiral water dividing tank on the inner wall is created, which effectively improves the heat exchange efficiency and heat dissipation performance of motor products

Aluminum extrusion motor shell is mainly used in micro motor, environmental protection air conditioning motor, water cooling air conditioning motor, air compressor motor, negative pressure blower, motor, electric tricycle motor, cooling tower machine, electric tool motor, gear motor, etc.

1. Specs:

| Item | Alloy | Temper | Surface | Usage |

| Common aluminum motor shell, inner hole non cutting motor shell | 6063、6063A | T5、T6 |

|

Non explosion proof motor |

| 6063 | Non explosion proof motor |

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

| Alloy | Chemical component(%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | ||

| Each | Total | |||||||||||

| 6063 | 0.20-0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45-0.9 | ≤0.10 | ≤0.10 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6063A | 0.30-0.6 | 0.15-0.35 | ≤0.10 | ≤0.15 | 0.60-0.9 | ≤0.05 | ≤0.15 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

Mill finish surface:

Color anodized surface:

Color Painted surface: