With many years of training in product design, mold design, casting technology and other engineering and technical personnel, Henan Chinalco has formed its own technological characteristics of die casting water cooled aluminum motor shell housing with spiral channel sand core after many experiments and years of accumulation. According to the product drawings confirmed by customers, we design the mold by ourselves, according to the product structure, combined with many years of experience in low-pressure casting. On the basis of ensuring the product strength, the product structure is modified to make the product beautiful in appearance, simple in structure, light in weight, and convenient for subsequent mold design and product casting.

Compared with the aluminum alloy extrusion section welding process, the low-pressure casting process of Henan Chalco has the advantages of high one-time forming efficiency, high product precision, high overall tensile strength, strong airtightness without pores, and low cost of mold development.

In the process of mold casting, the vacuum in the mold is removed to reduce the porosity and porosity of the product due to the gas generation from the sand core, and improve the one-time qualification rate of water-cooled shell casting.

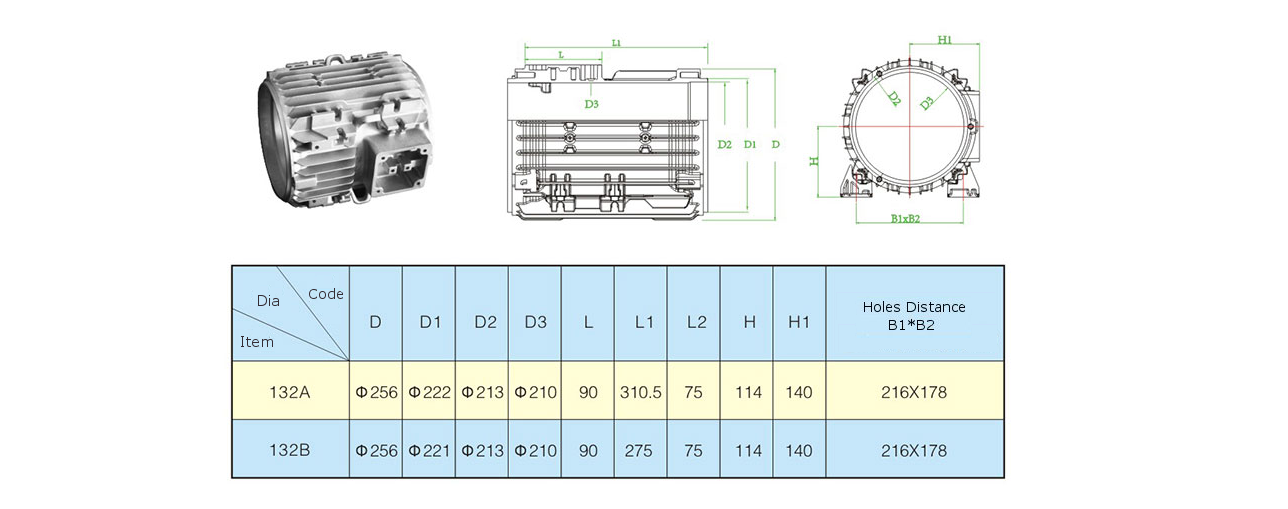

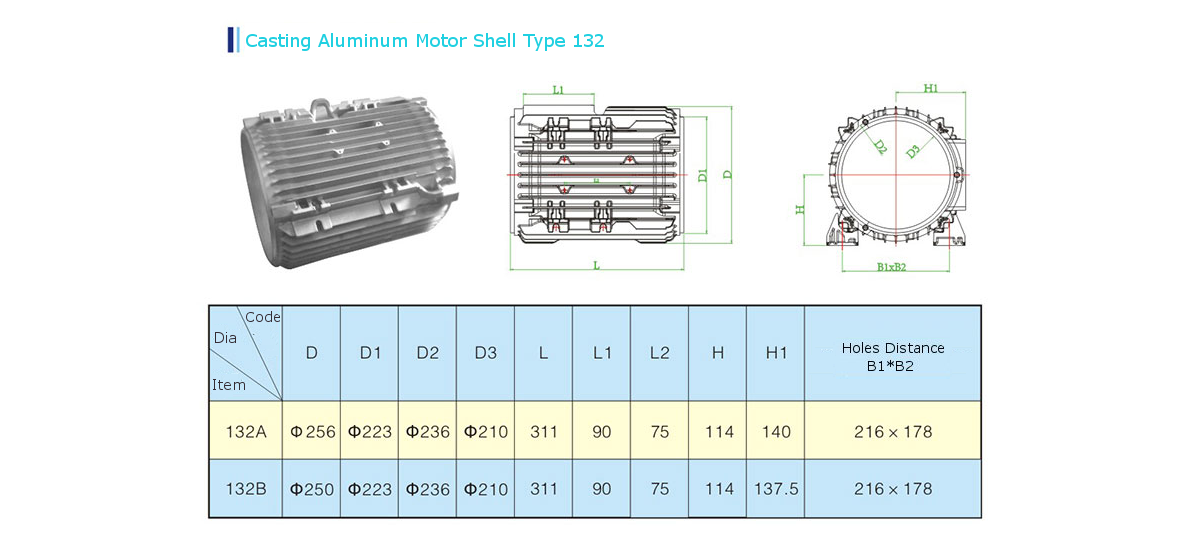

The low-pressure die casting water-cooled motor shell housing is used for the shell of the drive motor of new energy vehicles. The shell wall is designed with a spiral water channel, which divides the water inlet and outlet, so that the coolant can quickly enter the shell, cool the heat generated by the high-speed operation of the motor, and quickly take the heat away to ensure the continuous working efficiency of the motor.

Application area:

The products are used in the fields of new energy automobile motor, permanent magnet servo motor, motor vehicle and other efficient motors.

Compared with the aluminum alloy extrusion section welding process, the low-pressure casting process of Henan Chalco has the advantages of high one-time forming efficiency, high product precision, high overall tensile strength, strong airtightness without pores, and low cost of mold development.

In the process of mold casting, the vacuum in the mold is removed to reduce the porosity and porosity of the product due to the gas generation from the sand core, and improve the one-time qualification rate of water-cooled shell casting.

The low-pressure die casting water-cooled motor shell housing is used for the shell of the drive motor of new energy vehicles. The shell wall is designed with a spiral water channel, which divides the water inlet and outlet, so that the coolant can quickly enter the shell, cool the heat generated by the high-speed operation of the motor, and quickly take the heat away to ensure the continuous working efficiency of the motor.

Application area:

The products are used in the fields of new energy automobile motor, permanent magnet servo motor, motor vehicle and other efficient motors.