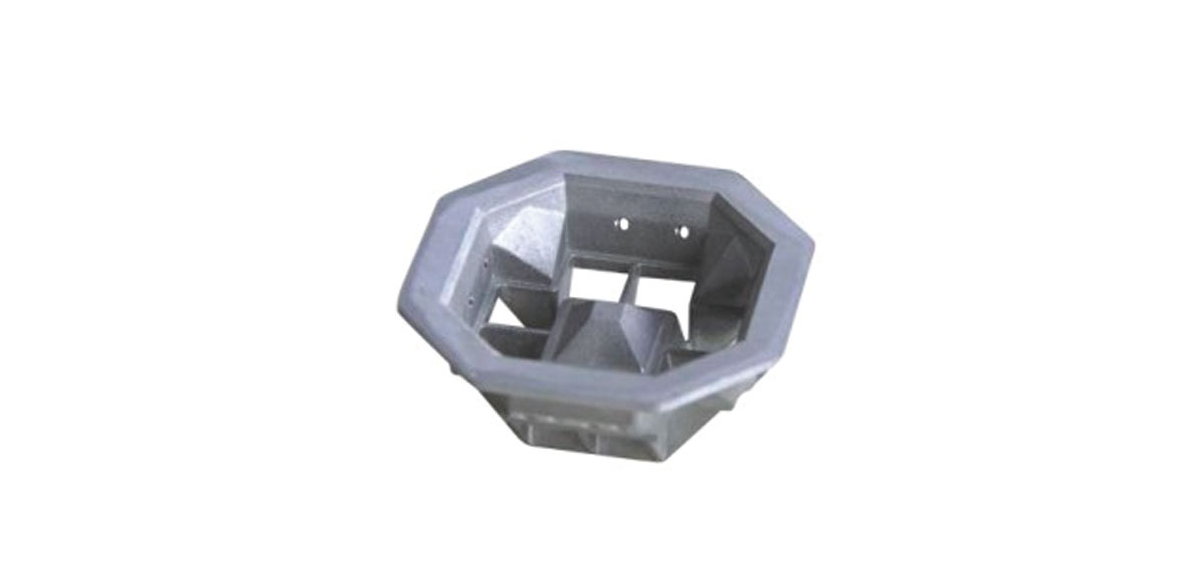

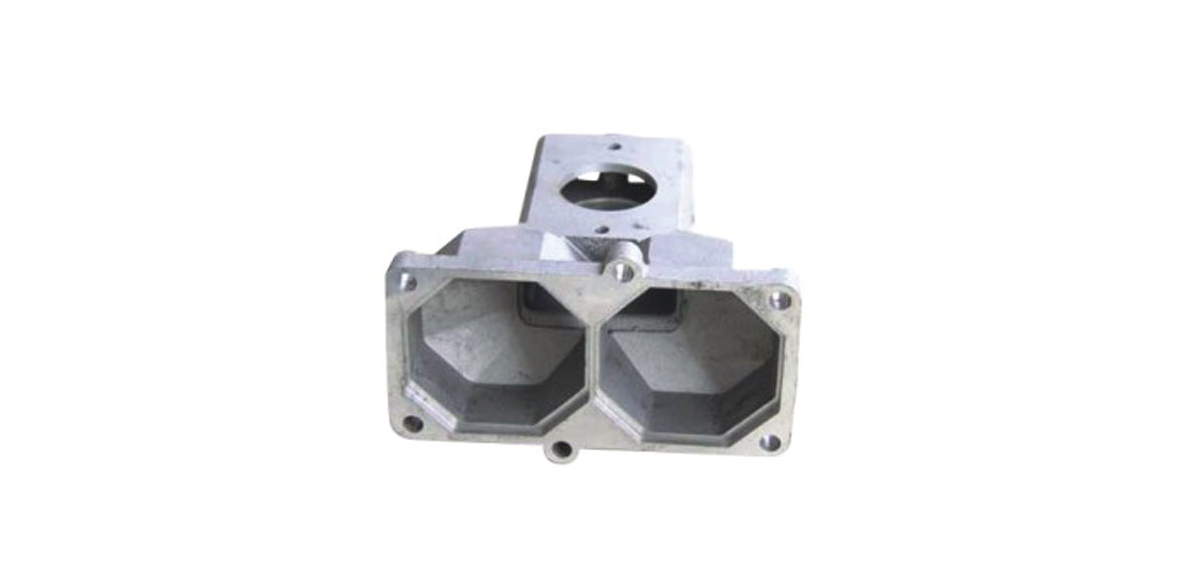

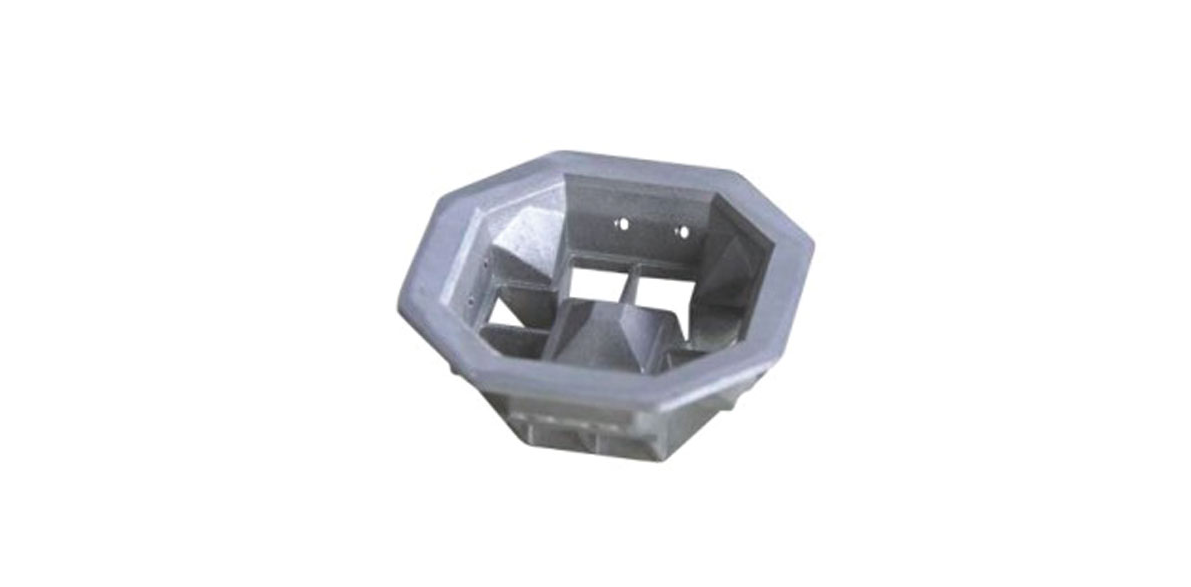

Die casting aluminum automotive parts is a kind of process method that the pure aluminum or aluminum alloy ingot is prepared according to the standard composition proportion, after being heated manually to become aluminum alloy liquid or molten state, and then the aluminum liquid or molten state aluminum alloy is poured into the mold cavity through professional mold or corresponding process, and then the aluminum parts of the required shape are formed through cooling.

The common methods of aluminum casting are sand casting, die casting, low pressure casting, precision casting, etc.

The die casting aluminum automotive parts of Henan Chalco is a kind of modern technology, which takes the low-pressure casting technology of electromagnetic pump as the core and combines the aluminum smelting and molding composite purification technology to produce aluminum castings. This technology can not only improve the quality of aluminum castings, but also improve the working environment, reduce the labor intensity, and realize automatic and modern casting production.

Aluminum casting automobile motor parts have some advantages that other castings can't compare, such as beauty, light weight, corrosion resistance and so on, which makes it widely favored by users, especially since automobile lightweight, casting aluminum alloy castings have been widely used in automobile industry.

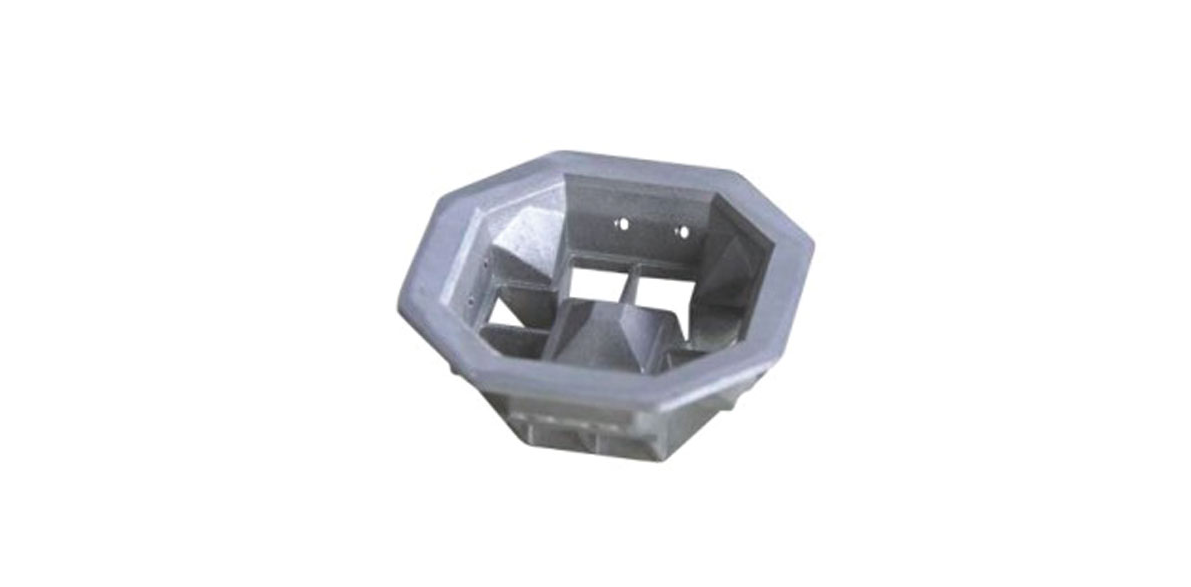

The common methods of aluminum casting are sand casting, die casting, low pressure casting, precision casting, etc.

The die casting aluminum automotive parts of Henan Chalco is a kind of modern technology, which takes the low-pressure casting technology of electromagnetic pump as the core and combines the aluminum smelting and molding composite purification technology to produce aluminum castings. This technology can not only improve the quality of aluminum castings, but also improve the working environment, reduce the labor intensity, and realize automatic and modern casting production.

Aluminum casting automobile motor parts have some advantages that other castings can't compare, such as beauty, light weight, corrosion resistance and so on, which makes it widely favored by users, especially since automobile lightweight, casting aluminum alloy castings have been widely used in automobile industry.