Squeeze casting, as an advanced casting forming process, combines the advantages of casting and forging, and has the advantages of simple manufacturing process, good air tightness and mechanical properties. Squeeze casting can realize lightweight, precision, small machining amount, material saving and forming energy reduction.

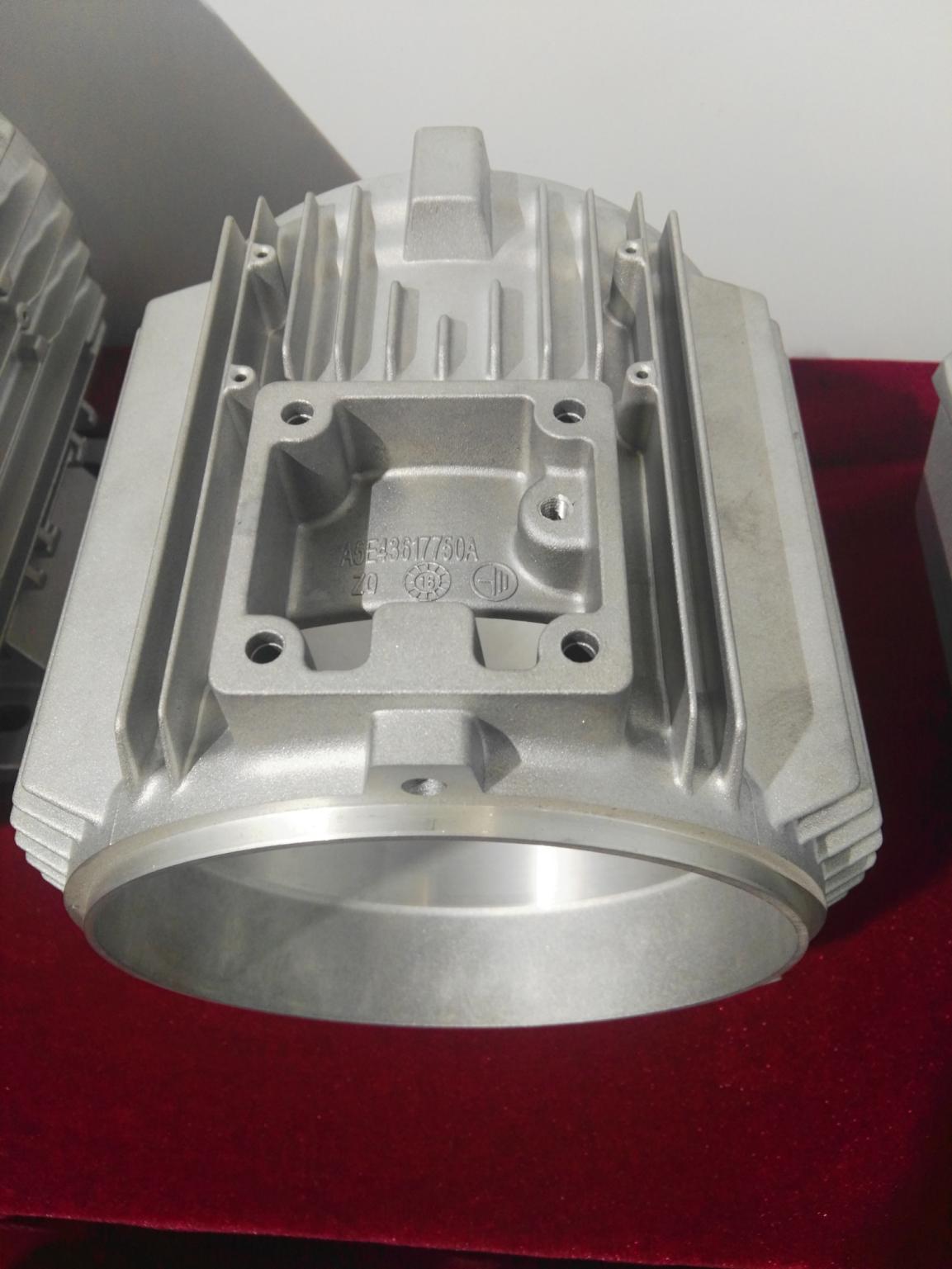

Function of die casting aluminum motor shell housing: 1) heat dissipation. Because it is often in high temperature, it needs water cooling system to meet the cooling requirements of the motor system. Although the cooling effect of water circulation is obvious, the structure of water circulation system is complex, and there is a risk of water leakage, so it requires a high air tightness of the die casting motor shell. 2) supporting function. When the end cover is installed on the end face of the motor shell, the LV motor shell needs to have certain strength.

The die casting aluminum motor shell series products adopt the dismountable foot assembly method, the horizontal and vertical installation methods are flexible, the direction of danger is diverse, the products have the characteristics of less cutting, light weight, high strength, good heat conduction and heat dissipation performance, beautiful appearance, scientific and reasonable structure, and fully enclosed protection, and the product performance reaches the international advanced level.