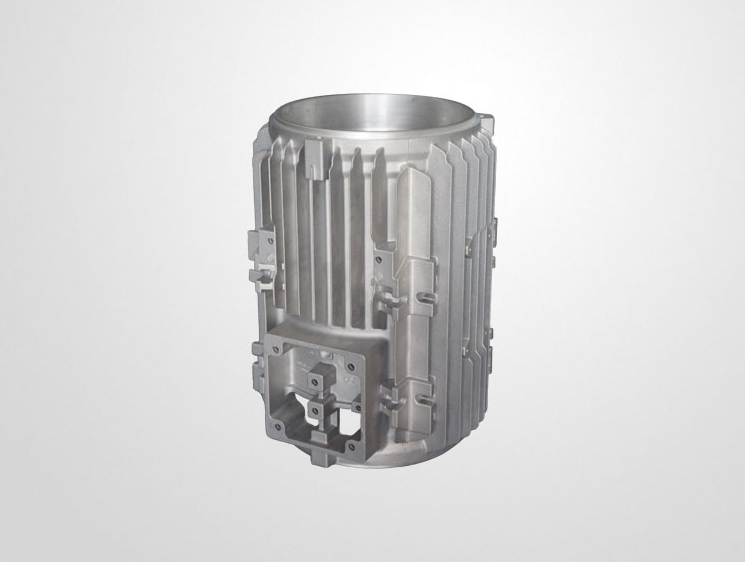

The aluminum die casting motor shell is not a complete cylinder. There are many convex laps and other auxiliary structures on the cylinder. The wall thickness of each part of the casting changes greatly. The stress of the casting during cooling and solidification will be relatively large. The deformation tendency of the casting can not be accurately predicted before. The diameter difference between the end of the straight cylinder and the aluminum motor shell of the initial casting is 15mm, and the ellipse is relatively serious. The diameter error of the end of the straight cylinder is within 1mm by setting ring-shaped casting bars at the end of the straight cylinder.

The inner cavity of the upper part of the casting is more complex, and there are more local bulges; there are more laps on the outer part of the casting; therefore, there are more "t" and "L" shaped hot spots in the casting, and it is difficult to supplement the casting. The molding operation is relatively simple, but the feeding of the aluminum die casting motor shell is very difficult, especially for the convex part of the upper inner cavity with complex structure. The riser is set at the upper end, but the thickness of the casting is thick, the thickness of the lower part is thin and the thickness of the upper part is high, so the feeding of the lower part is also very difficult. In addition, casting deformation is also a problem to be faced.

It is a very complicated problem to choose the rated power of aluminum die casting motor shell. Under load, if the rated power of the micro electric shell is too large, the aluminum motor shell is often in light load operation, and the capacity of the micro electric shell itself can not be fully developed. At the same time, the operation efficiency of the micro electric shell is low and the performance is not good, which will increase the operation cost.

The requirements of the rated power of the aluminum die casting motor shell are small, the current of the aluminum motor shell exceeds the rated current, the loss in the micro aluminum motor shell increases, the efficiency is low and the service life of the aluminum motor shell is affected, the insulation performance of the micro aluminum motor shell insulation material will be damaged or even burnt. Of course, the rated power of the aluminum motor shell is small, and the load may not be dragged at all, which will make the aluminum motor shell in the starting state for a long time and overheat and damage. Therefore, the reasonable selection of power and correct maintenance of the aluminum motor shell is essential.

In the process of motor operation, due to the effect of friction, the shell of casting motor will generate some heat. If the aluminum motor shell overheats, it will damage the normal operation of the motor, so the aluminum motor shell will be equipped with many blades or fans and lubricating oil to cool the aluminum motor shell. What kind of problem is reasonable for the aluminum motor shell? We need to explain this problem from different types of motors:

1. Explosion proof AC motor

If it is to drive high-speed oil pump, such as 2-pole motor with 2890 revolutions or more, the temperature shall not exceed 85-90 degrees. Because it is a high-speed motor, the temperature shall be generally controlled below 80 degrees in summer, exceeding the shutdown (considering the insulation grade of insulation coil). Also because the motor operates in the dangerous and explosive situation, in order to ensure that the explosion-proof inspector once every half an hour, the specific measurement: the motor surface temperature, controlled within the temperature.

2. Ground non explosion proof AC motor

For example, the commonly used 4-pole and 6-pole motors, because of the low speed of the motor, only need to refuel the bearing frequently. If it is more than 4-pole motor, the temperature of the aluminum motor shell should be kept at 70 ℃. If the bearing temperature is over 80 ℃, it is the cause of oil shortage, and regular maintenance is required.

Measuring position: Motor surface (high temperature near the lifting ring) motor bearing (side bearing cover surface).

3. DC motor

Because most of the DC motors have their own cooling fans, the temperature is controlled within 50 degrees, 60-65 degrees higher in summer.