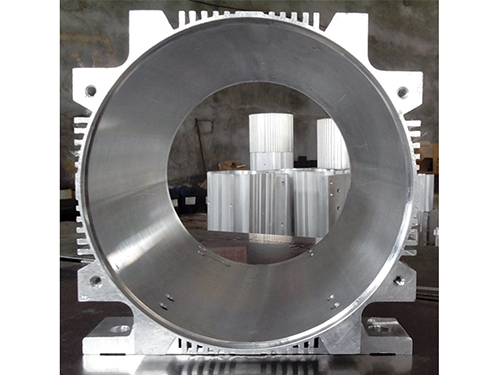

According to the composition and production process characteristics of aluminum alloy, it is usually divided into two categories: aluminum extrusion electric motor shell and Die casting aluminum motor shell. The main industrial applications are aluminum manganese, aluminum magnesium, aluminum magnesium copper, aluminum magnesium silicon copper, aluminum zinc magnesium copper and other alloys. According to their composition and performance characteristics, they are divided into five categories: rust proof aluminum, duralumin, super duralumin, forged aluminum and special aluminum. Aluminum alloy motor shell is mainly used in aluminum alloy motors Water cooled motor, servo motor, variable frequency motor and so on.

The water-cooled aluminum extrusion motor shell is welded by double-layer steel plate after antirust treatment. Through continuous circulation of cooling water in the interlayer of the shell, almost all the heat generated during the operation of the motor is taken away, so as to achieve the effect that the shell of aluminum alloy motor hardly emits heat to the outside.

When the motor in the aluminum extrusion electric motor shell is disassembled and the rotor is installed, care shall be taken not to damage the iron core and stator winding. Before drawing out the rotor, the air gap under the rotor and the end of the winding shall be padded with cardboard to avoid damaging the iron core and the winding when drawing out the rotor.

Disassembly of the rotor of the variable speed motor with small aluminum extrusion motor shell. For the rotor within 30kg, it can be directly drawn out by hand, holding one end of the rotor with both hands, pulling out the rotor with one hand, and holding the rotor core with the other hand to move out gradually. Disassembly of the rotor of the large aluminum shell variable speed motor. For the large aluminum case variable speed motor, if the two ends of the rotor are extended out of the frame for a long time, use the lifting equipment to lift it out. However, when lifting, attention shall be paid to the maintenance of the journal, stator winding and rotor core air duct.