Routine maintenance in the motor enclosure is very important to reduce and avoid motor failure in operation. The most important part is the circuit check and the root cause of the abnormal phenomenon elimination in time. In order to ensure the normal operation of the motor, in addition to the normal use of the operating procedures, operating procedures, pay attention to the normal monitoring and maintenance, also should be checked regularly, do a good job of maintaining the motor.

Our machinery and equipment can work normally, whether the motor can work normally is a very important part. Therefore, the maintenance of the motor is also very important. Many people always don't pay attention to the maintenance or don't know how to maintain it. When the motor has problems, the motor can only be maintained. The maintenance costs money and delays the work.

In general, the maintenance of the motor should pay attention to: keep the engine clean and dust-free; check the appearance of the motor frequently to see if there is any misplaced part; check the bearing replacement or gas frequently, and check the connecting thread of the incoming line.

During the manufacturing process, the motor can only bear the voltage between each phase and the positive phase. The insulation material is relatively weak. Good insulation will not occur in this fault generally. There may be insulation defects of your motor. The shell will be charged after the defects are exposed. So it is not the case that the motor shell has burn phenomenon, but also the cause of the motor. Some water-cooled motors will burn suddenly in some way in the process of use. Is there any reason for the shell of water-cooled motors? This problem is likely to be charged after the shell of the water cooled motor shell. The insulation between the motor winding and the iron core (and the shell of the iron core) breaks down, resulting in short-circuit current. Large short-circuit current causes the breaker to trip. If the switch breaker has no leakage protection, the leakage protection acts or does not, but the over-current or short-circuit protection, that is, before the motor short circuit, the breaker will only prevent the fault from expanding after the breaker trips.

The meaning of motor shell power selection:

It is a very important and complex problem to choose the rated power of motor shell. When the load is too large, if the rated power of the motor is the motor shell, and the shell is in the light load operation state, the motor capacity itself is not complete, and the motor shell enters the "carriage", and the working efficiency of the motor shell is low, and the performance is not good, which will increase the operation cost.

Motor shell rated power requirements, that is, "pony car", the motor current exceeds the rated current of the motor shell, the shell loss increases, the efficiency is low, the efficiency is low, the important thing is to affect the motor shell life, even if the overload is not large, the motor shell life will be reduced, the more load, the more; damage the insulation performance of the motor shell or even combustion. Of course, the rated power of the motor shell is small, and it may not drag the load at all, which will cause the motor shell to be damaged in the starting state and overheating for a long time. Therefore, the reasonable choice of power supply and correct maintenance is the reasonable use of the motor shell.

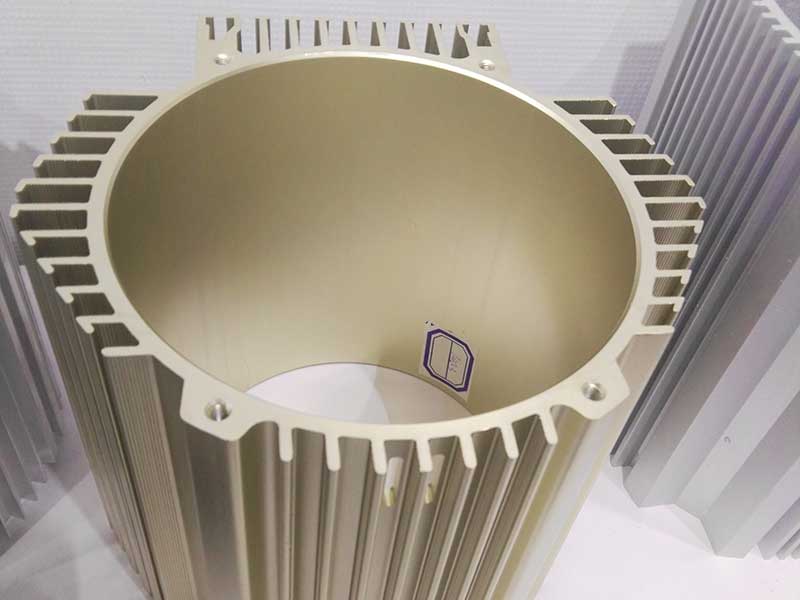

The casting tooling of the motor shell, the positioning plate and the chuck are connected through the bolt installation holes. The aluminum motor shell is in the external conical tube, and the driving power source driving pull rod is pulled into the conical block tube, which will be opened by a plurality of conical tube expansion blocks, and the aluminum motor shell is positioned from the internal tension. The end and the end of one end of the aluminum motor body are processed, and the end and the end of the other end are processed. After processing, the pull rod is reset, the conical block is withdrawn, the tensioning block is reset, the aluminum motor shell is loose, the motor shell is removed, and the aluminum motor shell is processed.

Both ends of the aluminum motor shell can be processed, achieving the following technical effects:

aluminum motor shell processing through the combination of cone tube and aluminum motor shell card cone block installation, can achieve a card installation for processing both ends and aluminum motor shell date, improve production efficiency more than twice.

The aluminum motor shell processing card installation can process both ends of the aluminum motor shell to avoid the influence on the parallelism of the two cards of the aluminum motor shell, improve the processing accuracy, improve the processing quality of the aluminum motor shell, and avoid the sweep frequency and noise during the use of the aluminum motor shell motor.

Through the use of aluminum motor shell processing tools, processing aluminum motor shell, aluminum water-cooled motor shell, through user testing and testing, the inner hole concentricity reaches 0.02mm.