1. Shrinkage and looseness, resulting in air leakage;

2. Due to air holes, die cast motor housing is directly scrapped.

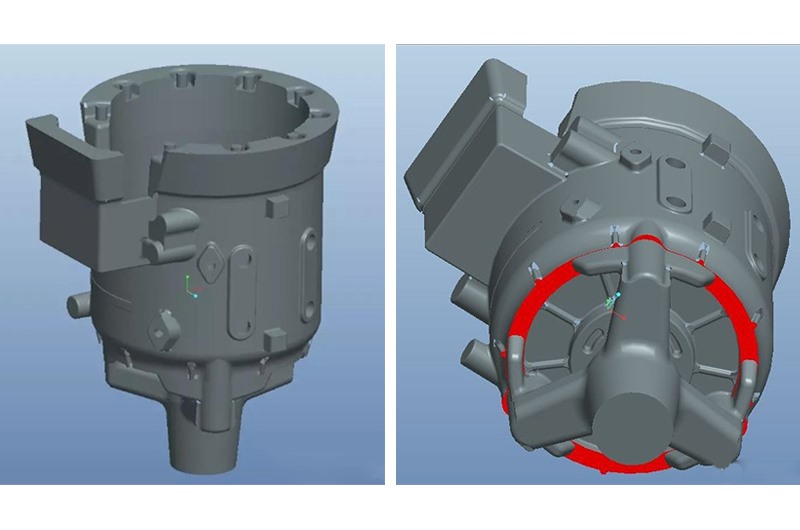

Die cast motor housing has an outer diameter of 240mm and a height of 200mm. There is a hollow water channel in the middle. It is formed with coated sand. Aluminum alloy material: A356; Because there is a flange at the bottom to form as a whole, the cylinder part is fed through the transverse sprue. The process diagram is as follows:

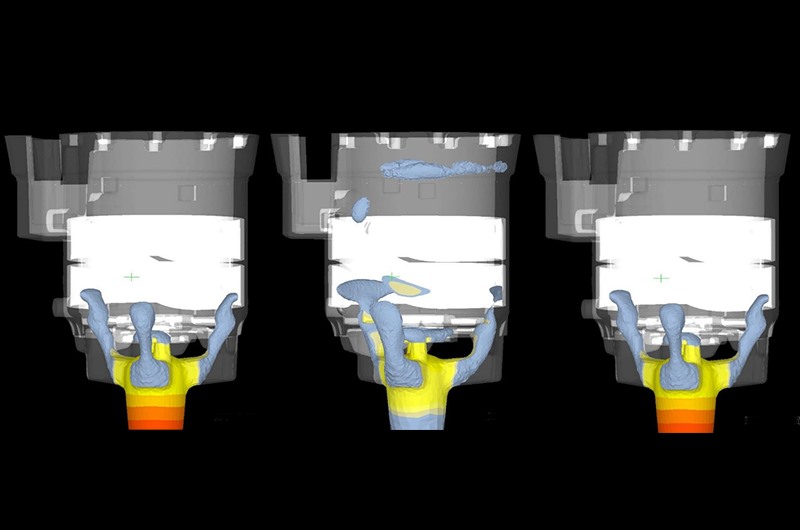

Comparison between the results of the first process analysis and the actual situation:

From the simulation, die cast motor housing has a large isolated solution at the upper end of the gate and shrinkage defects. The result of actual production is that there are serious shrinkage defects in this area. Finally, the product will be scrapped due to air leakage. The first model test failed.

Mold repair scheme: add shrinkage reinforcement in the ring.

The isolated solution at the upper end is obviously fed. The subsequent products are also consistent with the actual situation, realizing qualified sample delivery and mass production.